Privacy Curtains System

Date

2021-2023

Team

Adem Onalan, Brooke Williams, Marco Perry

Tags

Concept Ideation | Rapid Prototyping | Mechanical Engineering | Design for Plastic Injection Molding | CAD

Project Highlights

Overview

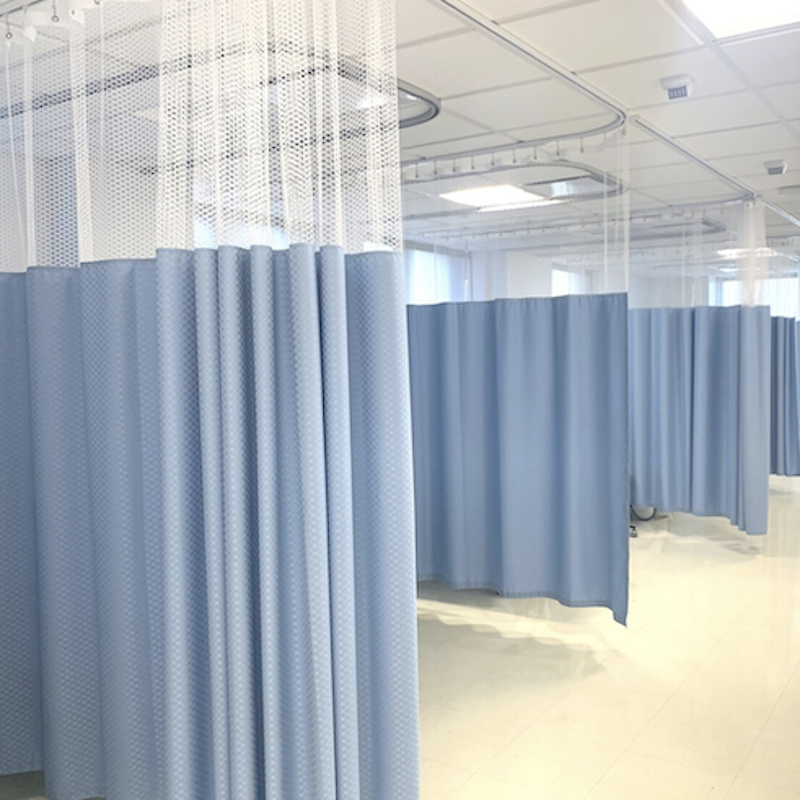

Hospital privacy curtains are prone to contamination and bacteria buildup, but removing, laundering, and replacing them is a tedious, time-consuming process. Our team set out to design a new curtain system to improve the ergonomics and user experience of changing out dirty curtains, encouraging more frequent replacements and better hygiene in clinical settings.

As lead mechanical engineer on the project, I was responsible for detailing mechanical concepts, building and testing prototypes, and supporting the manufacturing of custom injection molded components.

Product Requirements and Goals

Early on we developed specific goals for success:

- Dirty curtains must be able to be removed and replaced in 7 minutes or less.

- Eliminate the need for a ladder and assistance of a second individual during curtain replacement.

- Curtains must withstand repeated loads from industrial laundry machines.

- System must work with standard rail and hook systems and accommodate varying ceiling heights.

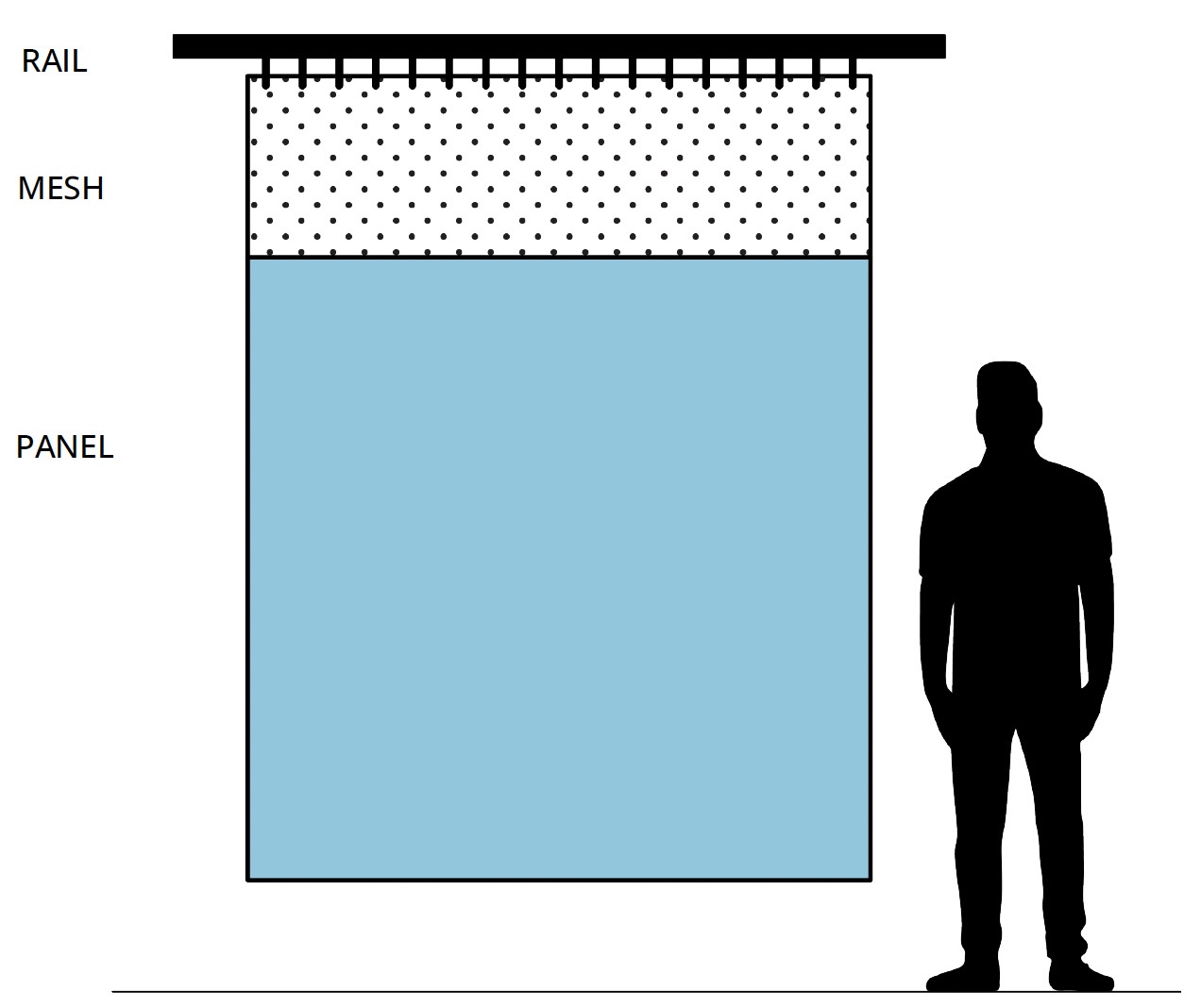

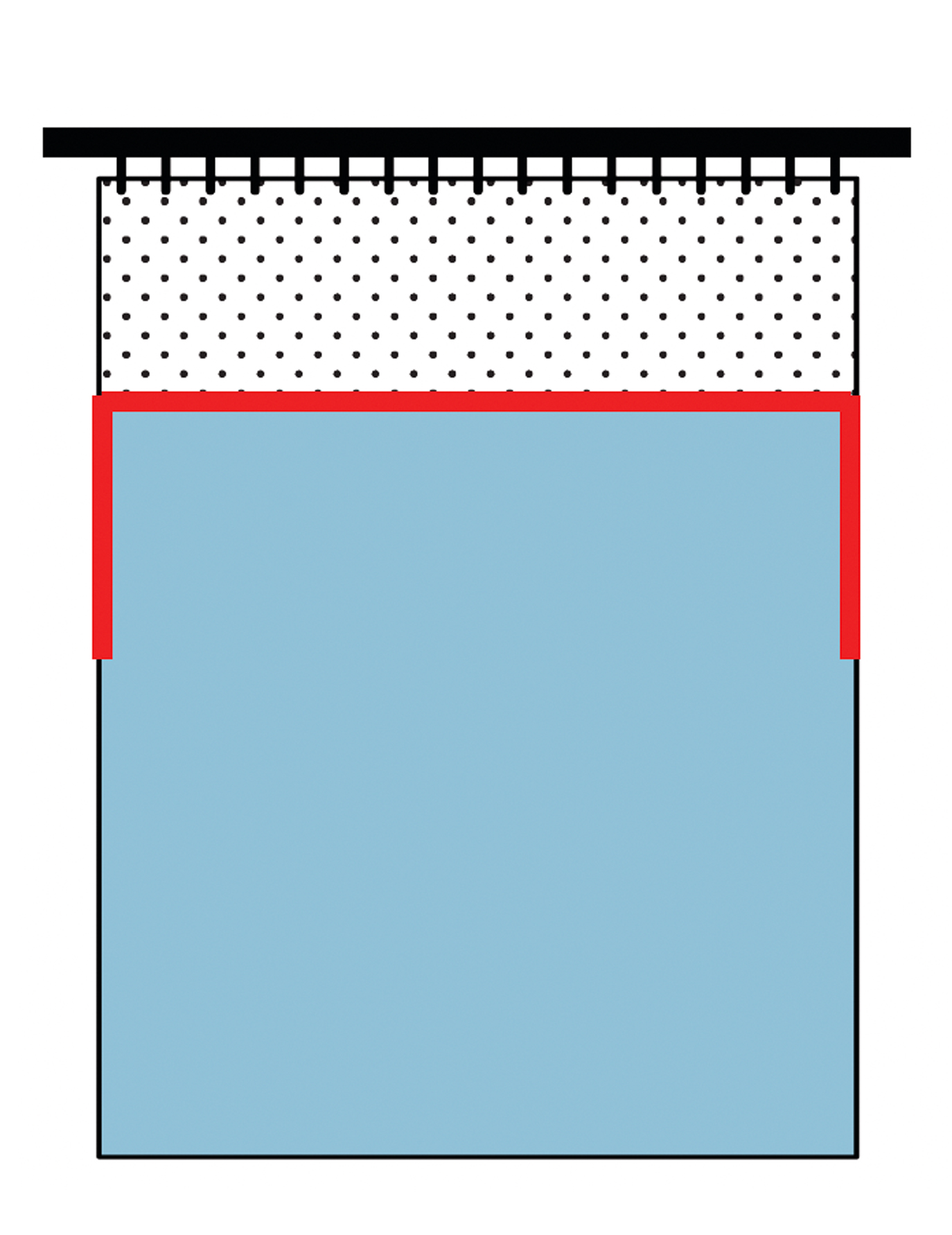

Standard Curtain System Elements

Rail — Mounted to or suspended from ceilings. Provides primary structural support for the system.

Mesh — Water-permeable part of the curtain. Required to meet regulations for fire suppression.

Panel — Part of the curtain that provides privacy, but also a surface that can easily become contaminated.

Concept Ideation

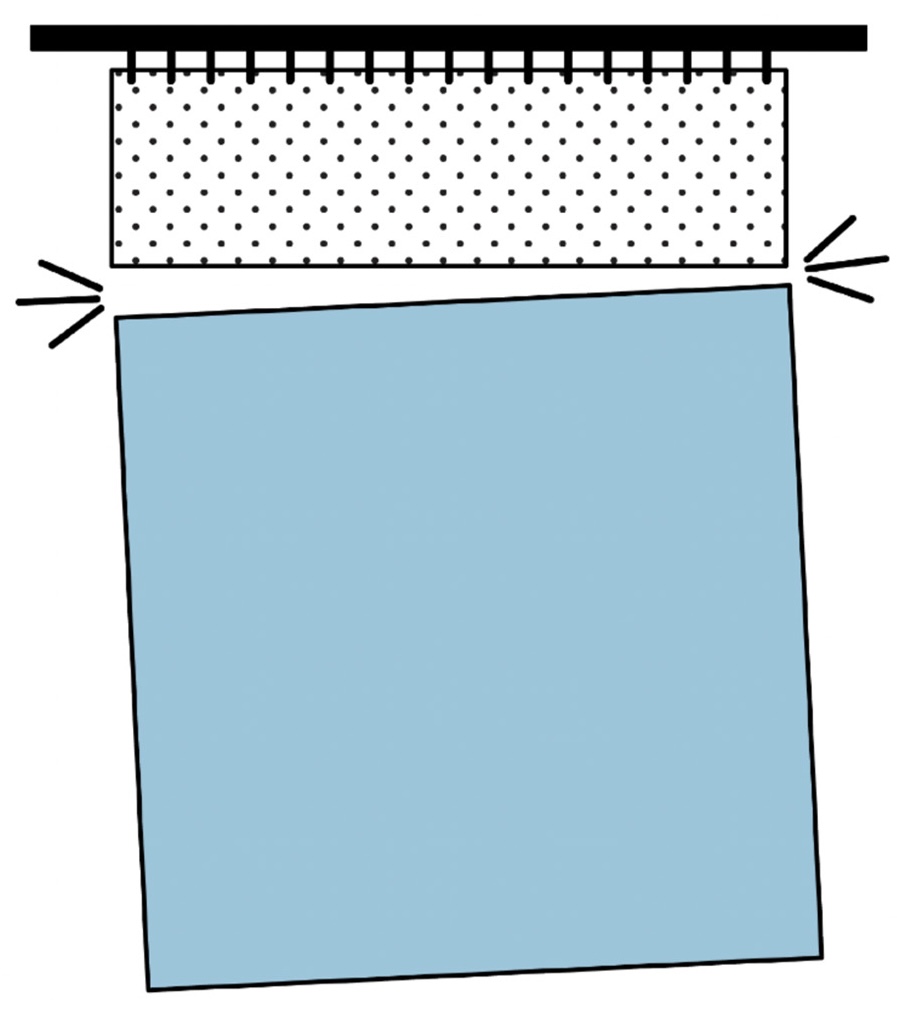

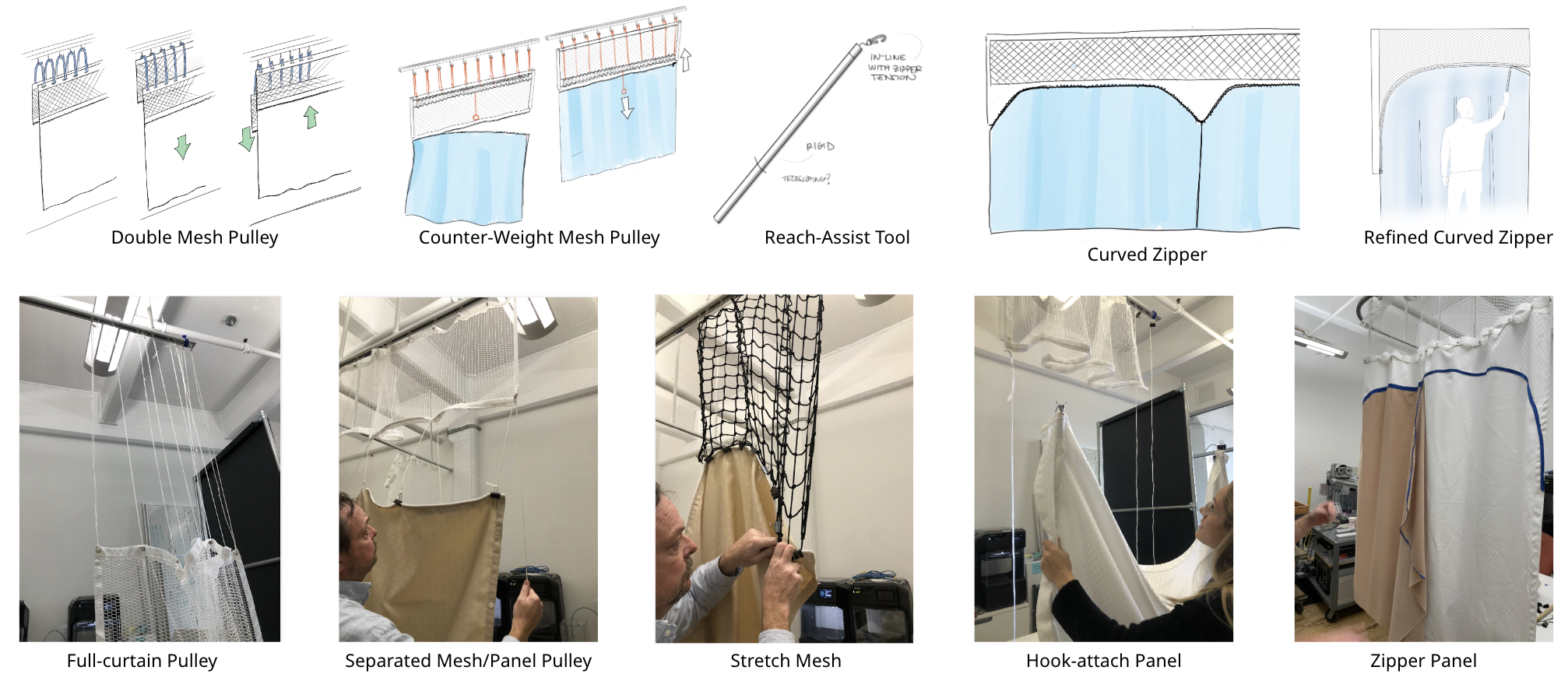

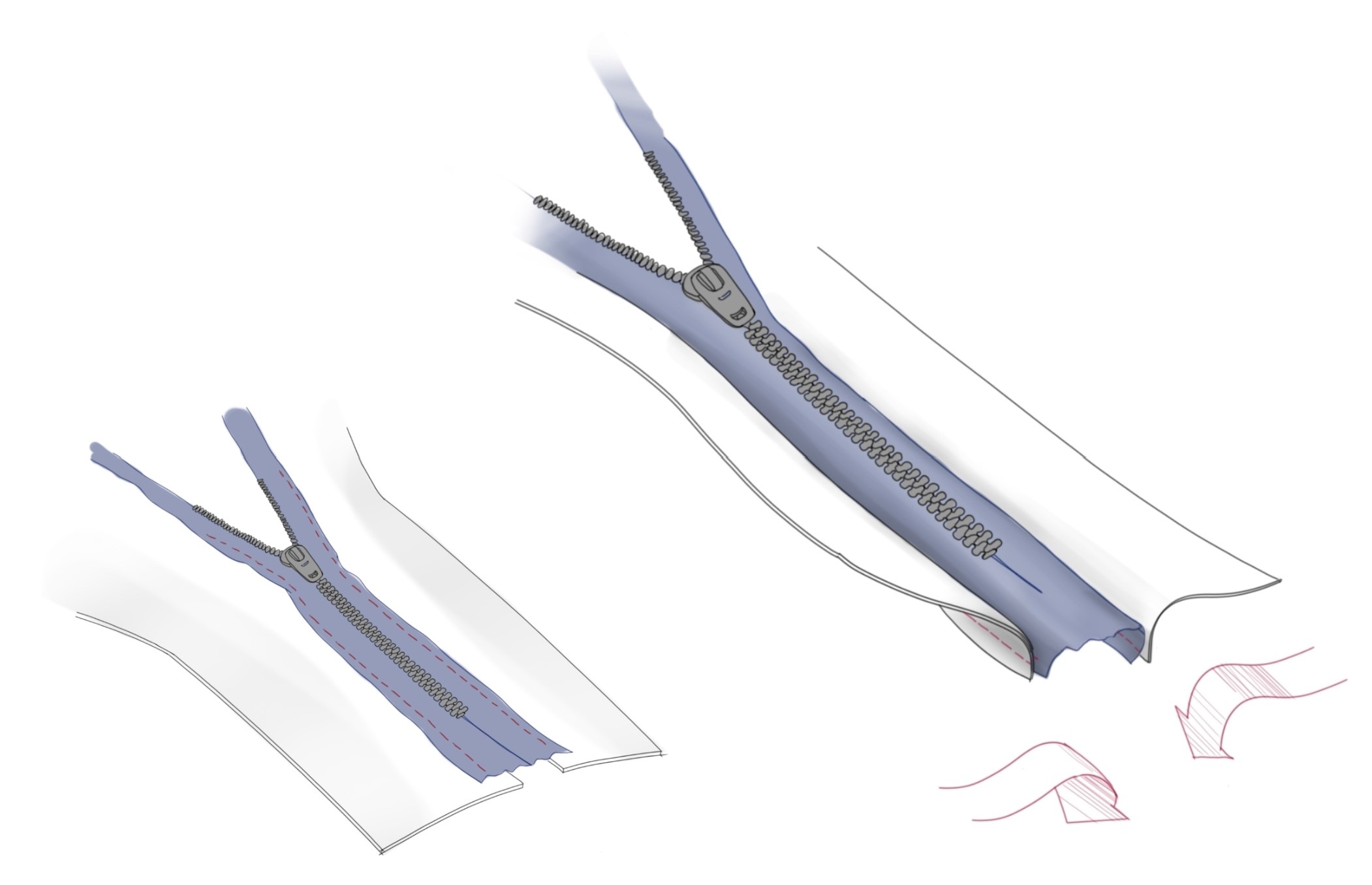

We installed a rail in our office and built several prototypes to test out concepts. After exploring a range of ideas, we found success with designs that separated the mesh from the panel and focused on refining a zipper-based solution that allowed for quick and easy detachment.

Curtains

Our design uses a zipper that runs up one side of the panel, across the mesh/panel interface, and down the other side. Extensions hang from the mesh to position the zipper's start and end points within easy reach.

We integrated snaps on the zipper extensions to offload the weight of a folded curtain, making zipping easier. We also incorporated snaps on the sides of the panels for connecting multiple curtains together.

We specified the sewing pattern for the corners to ensure a smooth transition and reduce snags while zipping.

Accessories

In addition to the custom curtain, we developed a Pull Handle and Reach-Assist Tool to further aid the user experience. I led the mechanical design and DFM for these components, working directly with the manufacturing partners, addressing manufacturing and assembly challenges, and reviewing and approving samples.